The ZZBO plant is constantly expanding its product range, and today it has more than 1000 units of manufactured equipment and spare parts for them. In 2018, the TEPLO brand was introduced to the heating equipment market, and the production area increased by 5,000 sq.m.

In connection with the rapid expansion of the range of ZZBO and TEPLO products, the requirements for the quality of manufactured products have also become more stringent. The consumer sector obliges the classification of certain products depending on its purpose and operating conditions, confirming membership in any class with a certificate from a certified laboratory or regulatory authorities.

At this stage of production expansion, the technical control department did not remain unchanged, each employee of which passed qualification tests and was certified in accordance with their job responsibilities.

The ZZBO Technical Control Department has highly qualified specialists with extensive experience, as well as its own non-destructive testing laboratory.

ZZBO NDT laboratory is certified and has a certificate (No. 56A150751 valid until 02/07/2023) to carry out non-destructive testing and diagnostics for steam and hot water boilers, internal gas pipelines of steel and metal structures (including: Steel bridge structures)

Methods of non-destructive testing and diagnostics:

– ultrasonic flaw detection;

– ultrasonic thickness gauging;

– capillary;

– VIK;

A manufacturer selling equipment that requires mandatory certification, as well as control by competent authorities, must have certified personnel and a laboratory, and measuring instruments must have certificates of conformity and be verified on a regular basis.

Non-destructive testing laboratory ZZBO complies with the requirements of the non-destructive testing system created on the basis of the Federal Law “On Industrial Safety of Hazardous Production Facilities” dated July 21, 1997 N 116-FZ

Here are some of the main regulations (extracted from the CERTIFICATION RULES AND BASIC REQUIREMENTS FOR NON-DESTRUCTIVE TESTING LABORATORIES, These Rules have the code PB 03-372-00 (Order of Rostechnadzor dated July 10, 2017 N 254)):

– PB 03-440-02 Rules for personnel certification in the field of non-destructive testing

– GOST R ISO 9712-2009 Non-destructive testing. Certification and certification of personnel

– Resolution of the Gosgortekhnadzor of the Russian Federation dated June 2, 2000 N 29 “On approval of the Certification Rules and basic requirements for non-destructive testing laboratories” (Registered with the Ministry of Justice of the Russian Federation on July 25, 2000 N 2324)

The use of these methods in non-destructive testing is carried out using special measuring instruments and tools, depending on the type of weld, the design of the product and the requirements for their manufacture and operation. The implementation of these control methods occurs in strict accordance with regulatory rules; each of these methods has its own GOST.

VIC is carried out to identify defects in welded joints, geometric seam breaks, and assess their quality visually and using measuring instruments.

Visual inspection can be carried out using the following tools:

-straight ruler LM-150;

- welding template USHS-3 and Usherov-Marshak template for measuring the dimensions of welded joints;

-caliper ShTs-1 150 (for measuring diameters and thicknesses);

- measuring tape 3-10m (for determining linear dimensions);

- a set of feeler gauges (for measuring gaps);

- lamps;

- test square UP 160x100mm (to determine the perpendicularity of the arrangement of parts relative to each other);

- template radius 32 pcs. ;

-measuring magnifying glass LI 3-10x (for assessing small defects in welded joints)

-Luximeter "TKA-Lux" (to determine the degree of illumination in the control zone)

Another important tool for inspection is ultrasonic flaw detectors.

Flaw detectors used for ultrasonic testing of welded joints must provide adjustment of the amplification (attenuation) of signal amplitudes, measurement of the ratio of signal amplitudes throughout the entire range of gain (attenuation) adjustment, measurement of the distance traveled by the ultrasonic pulse in the test object to the reflecting surface, and the coordinates of the location of the reflecting surface relative to beam entry points.*

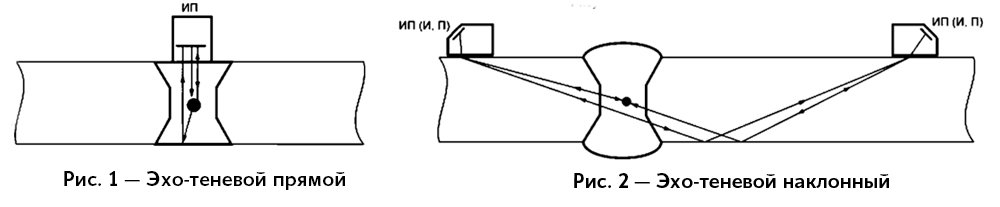

Some of the options for testing welded joints using the ultrasonic method:

– echo-pulse – mirror-shadow

– mirror-shadow

– echo-shadow

– echo-mirror

– diffraction

– delta

Ultrasonic testing - allows you to identify internal defects in a welded joint without destroying it.

Devices and tools:

– ultrasonic flaw detector UD2-70 (NPK “LUCH”), echo-shadow measurement method;

– a set of adjustment samples (to adjust the device to the required thickness and sensitivity)

CAMOZZI pneumatic gate - two-side

CAPILLARY CONTROL (abbreviated PVC) – used to detect surface defects in welded joints and determine their extent and orientation

What tools do the specialists of the Non-Destructive Testing Laboratory use? ZZBO:

– Sherwin penetrant (SHERWIN Babb-Co is a French manufacturer of materials for non-destructive testing) - this is an indicator liquid, usually red, that penetrates into the defect;

– white developer (pulls the penetrant deposited in defects onto the surface of the test object);

– cleaner (used to remove excess penetrant from the surface of the test object, before applying the developer)

– control samples for penetrant testing

What is it for? LNK

CAMOZZI pneumatic gate - two-side

The creation and certification of a non-destructive testing laboratory in companies specializing in the production of critical equipment or equipment for critical facilities is a necessary measure for the successful sale of this product, as well as expanding the sales market and further expanding production activities.

The main illustrative example is the quality control of welded joints in production pressure boiler equipment, gas supply and distribution systems, and metal structures (including bridges) used in construction.

CAMOZZI pneumatic gate - two-side

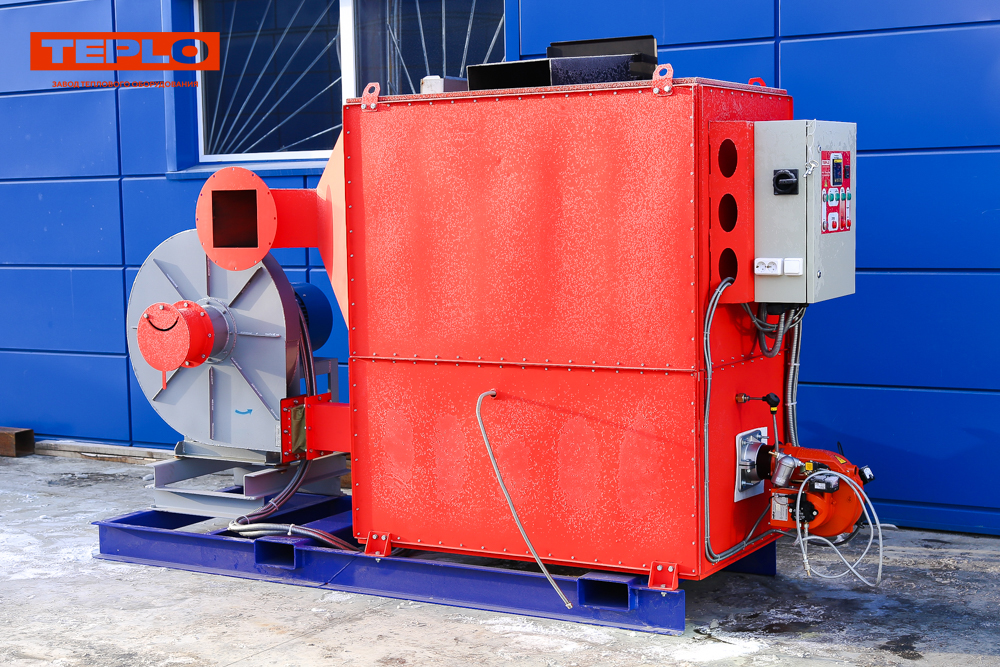

The designs of stainless steel units, the designs of medium-pressure thermal centers, water-heating boiler houses, heat exchangers of air heat generators, steam generators that are not subject to registration with ROSTEKHNADZOR, and other equipment from the field of LNK certification undergo high-quality and responsible control. This responsibility allows TEPLO to firmly consolidate its position in the Russian boiler equipment market.

TEPLO has successfully established itself in the international market as a supplier of reliable equipment. Numerous sectors of application, from heavy to agricultural industry, help expand the range of products, and successfully passed certification of the non-destructive testing laboratory guarantees the safe operation of the equipment.

/ CERTIFICATION RULES AND BASIC REQUIREMENTS FOR NON-DESTRUCTIVE TESTING LABORATORIES, These Rules have the code PB 03-372-00 (Order of Rostechnadzor dated July 10, 2017 N 254

/ GOST R ISO 9712-2009 Non-destructive testing. Certification and certification of personnel

/ Resolution of the Gosgortekhnadzor of the Russian Federation dated June 2, 2000 N 29 “On approval of the Certification Rules and basic requirements for non-destructive testing laboratories” (Registered with the Ministry of Justice of the Russian Federation on July 25, 2000 N 2324)

/ *clause 7, clause 7.1 GOST R 55724-2013 Non-destructive testing. Welded connections. Ultrasonic methods